The Mantair septic tank conversion unit

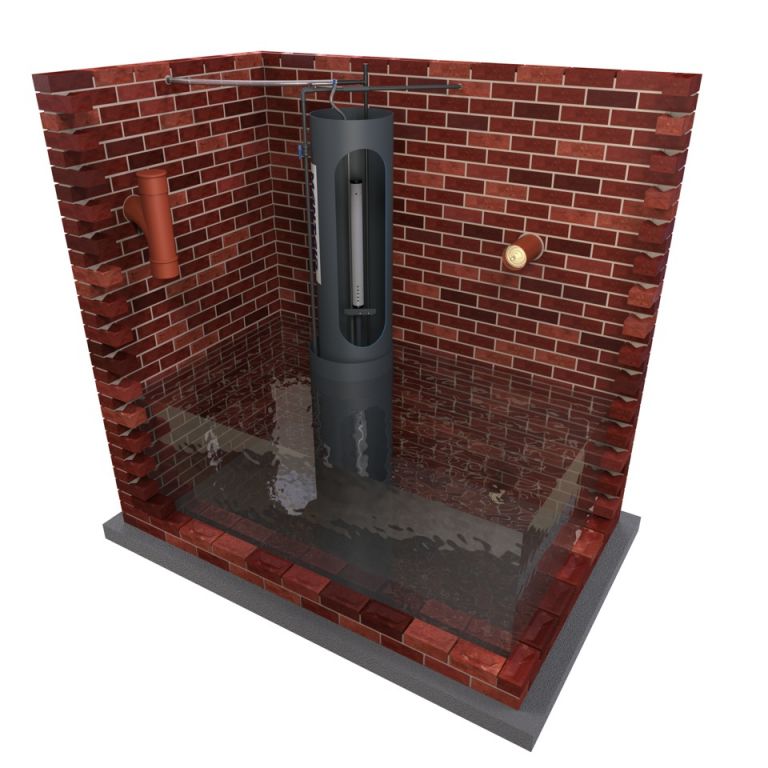

The Mantair septic tank conversion unit is a sewage treatment system specifically designed to fit within an existing septic tank or cesspool. This effectively converts the existing tank into a small sewage treatment plant producing a clear, odourless and harmless effluent. A discreet, reliable, and affordable solution solution for sewage treatment in off-mains homes and small commercial spaces.

In situations where the existing septic tank discharges untreated effluent to a watercourse or experiences soakaway failure, the Mantair septic tank conversion unit proves to be ideal. In addition, the Mantair unit is ideal for converting Cesspool holding tanks, removing the need for frequent emptying.

Why use the Mantair septic tank conversion?

- Accepted by the Environment Agency for discharge to natural watercourse under Permit Certification.

- Utilises the existing tank and fits through the manhole opening, providing a quick and efficient installation procedure.

- No disruptive excavations required, avoiding the disturbance to established gardens.

- No electrical pumps or motors installed within the underground treatment zone, providing lower maintenance and servicing costs.

- Efficient air blower is economical with low running costs.

- Works in high water table areas.

- Installations have a lifetime Process Guarantee.

- Produces a treated effluent in compliance with the Regulating Authorities.

How does the Mantair Conversion Unit work?

The septic tank conversion unit from Mantair is powered by a small air blower. The air blower can be located in either an existing outbuilding or in a small remote housing. The blower can be located up to 25 metres from the Mantair unit and is powered by domestic 240v electrical supply. It is a connected to the Mantair unit by a small bore MDPE pipe concealed underground. The blower provides the air that is required for the treatment process and to lift the treated effluent to the discharge point.

The Process

Once installed, the Mantair septic tank conversion unit separates the existing tank into two compartments / zones. The majority of the existing tank is transformed into an Aeration/Mixing Zone. Air is supplied to this zone via an aerator contained within a draught tube. Within this zone, the aeration and mixing encourages the growth of aerobic micro-organisms. This process degrades the sewage and breaks down large and heavy solids.

The contents of aeration / mixing zone where the micro-organisms are maintained in suspension are referred to as ‘mixed liquor’. As further flow enters the tank, part of the mixed liquor is displaced into the second compartment, referred to as ‘the final settlement zone’. Here the micro-organisms separate and form a thin sludge. This is continuously returned to the aeration/mixing zone, thus maintaining the levels of micro-organisms in the mixed liquor.

The liquid which remains in the upper part of final settlement zone is the treated effluent which is discharged from the Mantair unit via the Final Effluent Airlift.

The final effluent airlift controls the rate of discharge from the system and prevents any shock hydraulic loads from upsetting the treatment process. The use of an airlift enables the Mantair unit to discharge the effluent at a higher level than the tank inlet.

Specification

Mantair septic tank conversion units are designed to treat domestic sewage and to achieve a final effluent standard that complies with the Environment Agency’s requirements for discharge to a natural watercourse.

Model selection

The Mantair unit is available in population equivalents of (PE) 5 – 15. When sizing a sewage treatment system the British Water Flows & Loads Code of Practice should be used.

European Standard EN12566-3

EN12566-3 is the European Standard for ‘packaged sewage treatment plants’ up to 50 population equivalent. An integral part of the test procedure is structural testing of the packaged plant tankage. As the Mantair conversion unit does not include new tankage, it cannot be tested and EN12566-3 is not applicable.

As there is not a European Standard for ‘in tank’ Conversion Units, it is not possible for them to obtain a CE Mark. However, all components used in the manufacture of the Mantair conversion unit comply with the relevant European Standard.

The Environment Agency recognises the Mantair conversion unit as a sewage treatment system and authorises its use under Permit Certification, allowing the treated effluent from the system to be discharged directly into natural watercourses.

The Mantair unit should not be confused with other products marketed as ‘conversion units’ which involve the installation of additional tankage downstream of the existing septic tank. As new tankage is required these products can be tested under the European Standard. These products however do not ‘convert’ the existing septic tank, but provide biological treatment in additional tankage.

Installation

The Mantair septic tank conversion unit is supplied and installed by our ‘in house’ Contracts Division or an approved Mantair Licensed Contractors, dependent on the geographic location of the site. The system is not available through wholesale or retail outlets.

Licensed Contractors

All Licensed Contractors offer a comprehensive service. This includes an initial site survey, guidance and advice on system selection, complete installation and commissioning of your treatment plant and full after sales service.

Contact Us

For further assistance and advice, contact us on 01255 853890 | enquiries@mantair.com – or by filling out the form on our contact us page.