Marsh Sewage Treatment Plant Problem & Solution

RSPB Minsmere Sewage Treatment Plant Upgrade

Background

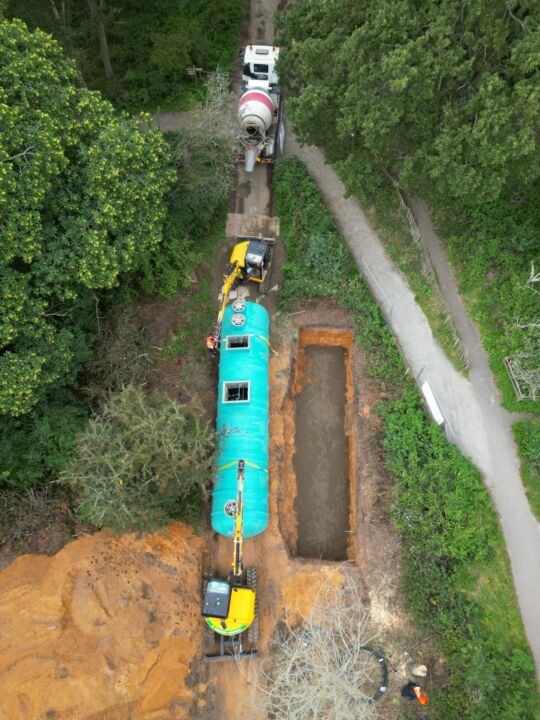

RSPB Minsmere, one of the UK’s premier bird reserves, required an urgent upgrade to its failing sewage treatment system to accommodate the needs of their visitor center, including a cafe. The existing treatment plant had failed, due to age and the expansion of the site. This lead to operational challenges and environmental concerns. The solution was to install a 225PE Marsh Ultra Polylok treatment plant, coupled with a twin pumping system for discharge back into the site’s existing pumping main. The project included a number of complexities due to environmental, logistical, and wildlife concerns, as well as the challenges posed by the COVID-19 pandemic.

Key Challenges

Restricted Site Access

The location of RSPB Minsmere is surrounded by small villages with narrow roads, making access for large vehicles, cranes, and heavy machinery difficult. Tree coverage limited the possibility of using cranes on-site, necessitating alternative methods of tank delivery and installation.

Pandemic Delays

The initial site visit and subsequent project work occurred during the COVID-19 pandemic. The process of applying for and receiving a environment agency permit took over 18 months due to reduced staffing and delays from government agencies.

Onsite Communication

The remote nature of the site meant there was no mobile phone signal, so communication between team members was reliant on walkie-talkies.

Wildlife Considerations

RSPB Minsmere is home to a variety of wildlife, including birds, bats, and Adders. Bat nests were found in proximity to the installation area, requiring careful planning to avoid disturbing them during the project. Work schedules were also carefully planned to avoid disruptions to visiting birds, which were a primary attraction for the center.

Public Safety and Access

The RSPB Minsmere visitor center remained open to the public during the installation, necessitating stringent health and safety measures to protect visitors. It was critical that the installation work did not interfere with visitors’ experience or present any danger to the public.

System Switchover

The treatment system upgrade needed to be conducted seamlessly to ensure that there was no downtime for the visitor center’s cafe. Ensuring the new system was fully operational prior to switching from the old system was a priority to avoid service interruptions.

Solution and Execution

Despite the challenges, the installation of the 225PE Marsh Ultra Polylok treatment plant was carried out successfully. The following steps were taken to address the complexities:

- Logistics and Access: Due to the inability to use cranes, smaller vehicles and manual handling methods were employed to transport the tanks and other equipment to the installation site. This required careful coordination and planning.

- Wildlife Protection: Bats and birds were carefully monitored, and work was scheduled around sensitive nesting times. Environmental experts were consulted to ensure compliance with wildlife protection regulations.

- Safety Measures: With visitors still present on-site, temporary barriers and restricted zones were created around the work area. Site-specific safety protocols were developed to mitigate any risk to the public and to allow continued access to the visitor center.

- System Redundancy: The existing pumping station was maintained while the new system was being tested and commissioned. This ensured that the cafe’s wastewater treatment was uninterrupted throughout the installation period.

Outcome

The project was completed successfully, with the new treatment plant fully operational and seamlessly integrated into the site’s existing infrastructure. The collaboration between the installation team, environmental agencies, and RSPB Minsmere ensured that the project met environmental standards and caused minimal disruption to wildlife and visitors.

The new system has provided a sustainable solution to the site’s wastewater treatment needs, ensuring the long-term operation of the visitor center and cafe without compromising the surrounding environment.

Conclusion

This case study highlights the importance of balancing infrastructure upgrades with environmental and public safety considerations, particularly in sensitive and remote locations.

If you are a business that needs a new sewage treatment solution, but has multiple site complexities, please get in contact.

For further assistance and advice, contact us on 01255 853890 | enquiries@mantair.com – or by filling out the form on our contact us page.